MegaPAC L1, L2 & L3

Now with PCT Multi-touch screens

Multi-touch portable workstations

The latest touch screen technology is now available on large deployable workstation screens. The ACME MegaPAC is now available with Projected Capacitive Touch screens. Single, dual and triple screen workstations are available, and whichever system suits your needs, all screens support multi-touch input.

Almost everyone today is using touch-enabled mobile devices, tablet devices, or laptops on a daily basis. Multi-touch capabilities are merely table stakes now in mobile computing devices, and the gaming or signage industries.

Touch screens on mobile devices were revolutionized in 2007 when Apple released the first iPhone. Of course, Apple did not invent the technology, but it was the first time it was made available on a mass-market device. What made the iPhone tech interface different? Gestures, pinch and reverse pinch- to zoom out and in, swiping, etc. Before that, touch devices were restricted to single points (like clicks).

Now multi-touch gestures are available on the 24” displays of the MegaPAC portable workstation.

If we take a look at the original touch-screen technologies we can trace the evolution and understand the technology behind multi-touch displays:

Some of the earliest touch displays used infra-red beams of light in a grid. Sensors would ordinarily ‘see’ the beam, but when a finger was placed on the display, it broke one or more beams, giving the touch screen controller an X & Y coordinate for the ‘break’ and provide a ‘touch’ input. This technology is still in use as it allows the display glass to be made really tough, unlike the restive and capacitive alternatives.

IR Touch screens are suitable when a harsh environment (for example one that will be used by the public) is expected. They are:

- Vandal-proof, wear-resistant

- Maintenance-free, longer life expectancy

- Versatile touch object (Pointer or finger or glove)

- Super transparency (no membranes between the display and user)

- Operable in various light conditions, indoors and outdoors

These sorts of touch displays are usually found in POS, ATM, Kiosks, gaming machines, and industrial control systems.

Touch Screen Technologies

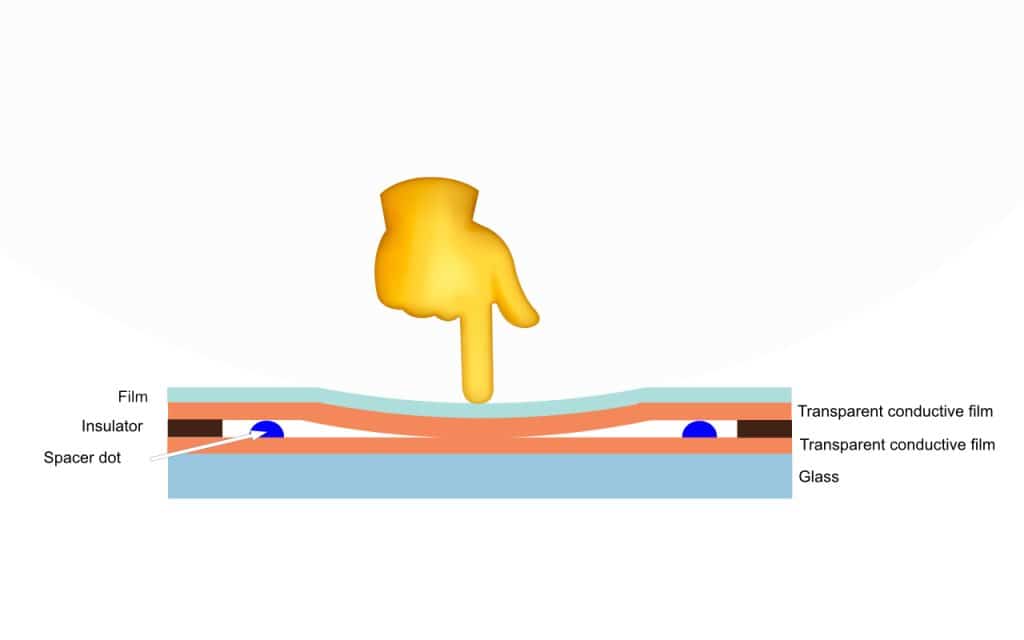

Resistive touch screens

Resistive touch screens

Resistive touch screens work by sensing the closing of a contact between two conductive membranes. There are typically an array of dots, visible upon close inspection, that holds the two membranes apart until the ringer or pointer closes the gap by deforming the membrane. This highlights one of the advantages of resistive screens over capacitive technologies – the pointing device does not need to be conductive, so a fingernail, a glove or a stylus can all work. Resistive touch screens can be quite precise and don’t suffer from calibration drift as much as some capacitive screens.

Disadvantages are that there are at least two layers of membrane – typically plastic – between the display and the user, which reduces light output, and therefore reduces brightness. Over time, the flexible membrane can become fatigued and ‘cloudy’ further reducing display clarity. The other big disadvantage is that resistive touch screens can only detect a single pressure point – so there are no multi-touch gestures like pinch to zoom.

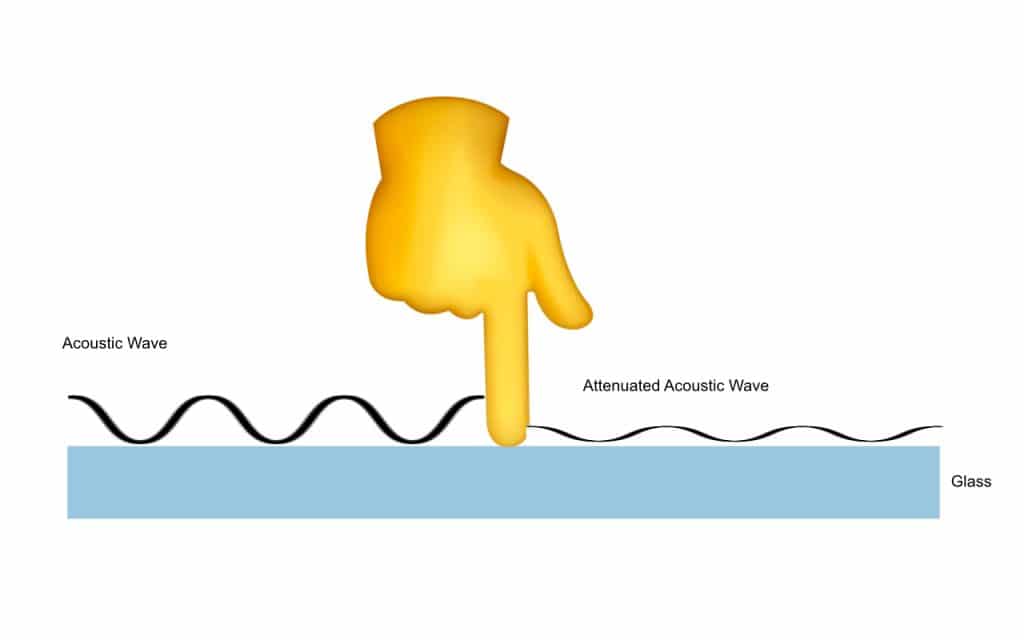

Surface acoustic wave

Surface acoustic wave

Surface acoustic wave touch screens work by sending an ultrasonic wave (ultra-sound wave) across the surface of the glass. Sensors detect the reflected wave and in some cases the attenuated wavefront that is caused by the pointer or finger. This is then translated into an X-Y coordinate for the touchpoint.

Traditional capacitive touch

Traditional capacitive touch

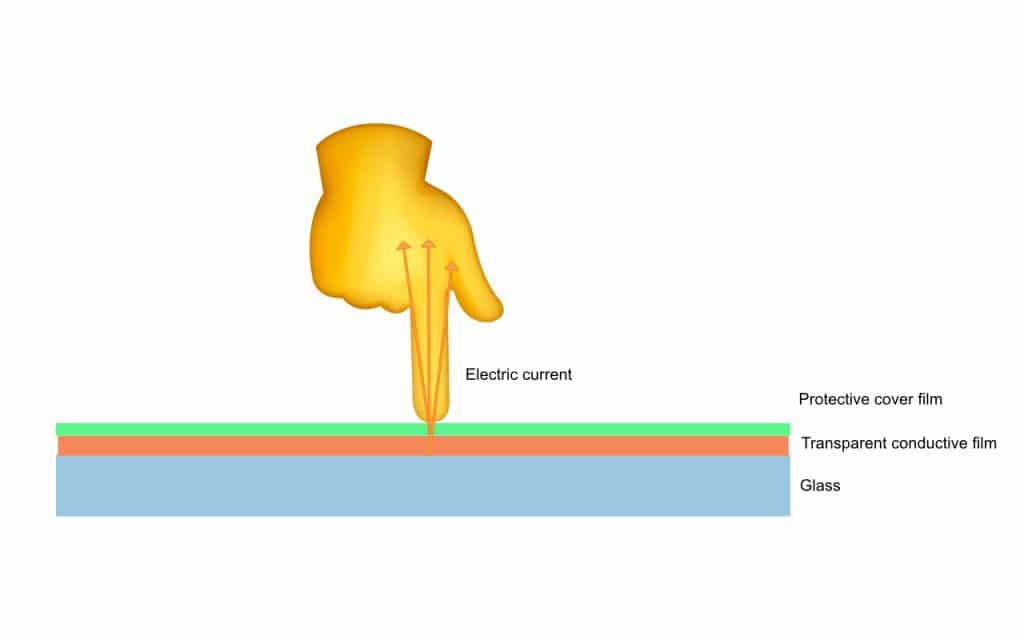

Otherwise known as surface capacitive – work by detecting a change in capacitance of the field in front of the screen caused by a conductive entity of some sort. Usually a finger. Capacitive touch screens are commonly made of two layers – a surface insulator and a transparent conductive layer below it. As the human body is an electrical conductor when the touch panel is touched with a finger the electrostatic field of the panel is distorted. The touch screen controller then decodes the changes in capacitance and returns a touchpoint to the system. The advantages are that there is no membrane that needs to flex, so the touch-screen should last longer. Disadvantages include possible drift over time on large displays, which require periodic re-calibration. Because the sensor is a glass panel, there is less visual degradation than with resistive screens.

Projective capacitive touch

Projective capacitive touch

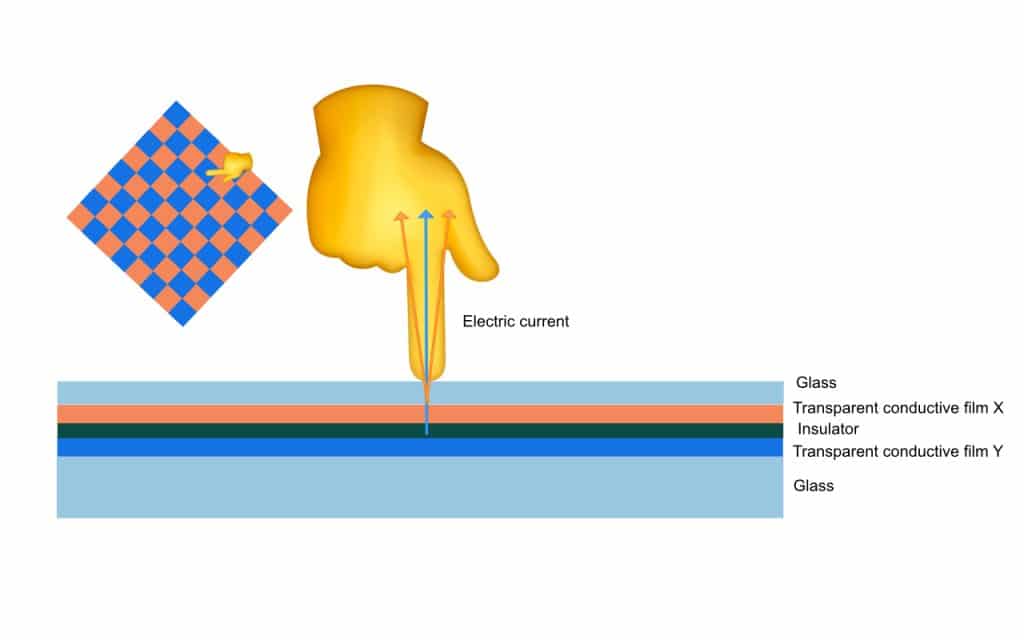

Instead of one capacitive sensor, there are many, usually on two layers of transparent conductors.

Projected Capacitive Technology (PCT) is fast becoming one of the most prevalent touch technologies for touchscreens. PCT technology is what allows us to tap, pinch, zoom, and scroll with various gesture controls and using multiple fingers, and can be used in a wide range of applications from consumer devices to commercial products.

PCT devices identify touch by measuring the capacitance at each addressable electrode in a dual-layer grid. When you touch the surface of a capacitive device, there is a disturbance in its electrical field (capacitance), which allows the device to determine when and where the touchpoint occurred.

PCT technology uses two main types of sensing methods, self-capacitance and mutual capacitance, each having its own advantages and disadvantages. In short, self-capacitance devices offer a higher signal strength and sensitivity to touch but does not support multi-touch (more than 2 touch-points) like mutual-capacitance devices.

“Projected capacitive technologies detect touch by measuring the capacitance at each addressable electrode. When a finger or a conductive stylus approaches an electrode, it disturbs the electromagnetic field and alters the capacitance. This change in capacitance can be measured by the electronics and then converted into X,Y locations that the system can use to detect touch” ( from 3M)

ACME’s addition of PCT technology to the MegaPAC results in a superior portable computing platform with a durable, UHD multi-touch touchscreen. The MegaPAC is a high performance, high-fidelity interactive solution that meets customers’ expanding user interface requirements.

For more information please contact sales@portexa.com